Fiberglass Loses R-value And Cracks In Metal Buildings

Once fiberglass insulation gets wet (and it will get wet, due to condensation) it will lose r-value! Water trapped between fiberglass insulation and the exterior of a building will also cause mold, fungus growth, rust and oxidation - Conditions that will degrade the metal and shorten the service of the structure. In addition, fiberglass insulation does not prevent radiant heat transfer (the primary source of heat-flow in and outside your building). The Prodex Total r-value is not affected by humidity. This feature cannot be over emphasized. There will always be some humidity in a metal building and your insulation must work in these conditions.

Take a look at the white vinyl facing the next time you're in a metal building - It will be either sagging, or sagging and flaking. This is due to the added weight of water. Behind the white vinyl is a wet, mold filled blanket that will eventually cause the white vinyl to crack and fall off. At some point, when you're exposed to the toxic fibers, you'll be forced to remove the insulation - Hopefully before it does too much damage to the metal framing.

Fiberglass insulation is composed of woven fiber stands. The fiber strands contain hundreds of small air pockets. The insulation’s R-value is derived from the air-pockets between the fibers. Once exposed to moisture, the air pockets fill up with water (rather than air) and the insulation loses R-value - Its ability to stop heat transfer, in and out, of the building.

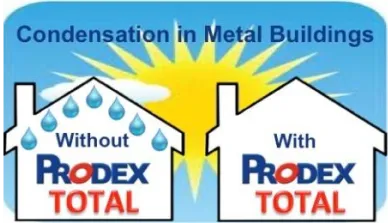

Metal buildings condensate! Fiberglass insulation will get wet.

When used in conjunction with Prodex Total, fiberglass insulation can be effective in a metal building.

Prodex Total will keep moisture out of the fiberglass insulation. Prodex allows the fiber air pockets to remain dry. It's important that fiber air pockets remain dry. Once wet, fiberglass insulation loses r-value.

Get More Value out of Fiberglass Insulation!

Fiberglass insulation should be installed with a vapor barrier between it and the metal sheeting. A vapor barrier will protect the fiberglass from moisture. Better yet, you want to prevent the condensation from occurring, rather than just blocking it from reaching the fiberglass insulation. Prodex Total is the perfect complement to fiberglass insulation. Here’s why:

R-value Protection

Fiberglass R-value comes from the air pockets between the fibers, not the fibers themselves. When moisture fills these air pockets, the R-value decreases.

How Prodex Total Helps

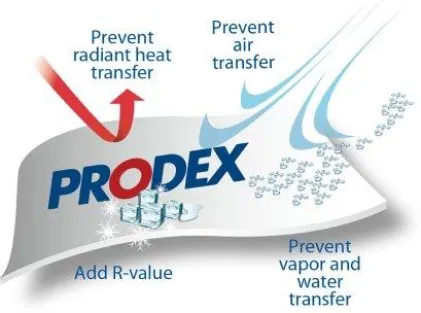

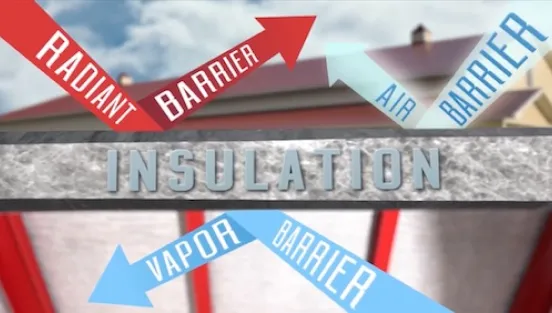

Installing Prodex Total (insulation + radiant barrier + vapor barrier + air barrier + condensation eliminator) between the fiberglass and metal sheeting helps keep the fiberglass dry, preserving its R-value over time. Prodex Total will create an envelope (a building within your building). It will keep the metal sheeting temperature consistent on both sides. That is how condensation (moisture that gets to your fiberglass insulation) is prevented.

Prodex Total will create an envelope (a building within your building). It will keep the metal sheeting temperature consistent on both sides. That is how condensation (moisture that gets to your fiberglass insulation) is prevented.Increased Energy Efficiency

When used in conduction with Prodex Total, you'll get the R-value performance from fiberglass that you expected. You also enjoy the benefits of Prodex Total: Prevents condensation, vapor barrier, added R, radiant barrier and air barrier protection.

If fiberglass is used as your stand-alone metal building or pole barn insulation, you'll have moisture issues (typically hidden behind facing), loss of r-value (consequence of the moisture), and heat gain. It needs a vapor barrier to protect it!

Advantages and Disadvantages of Spray Foam Insulation

Advantages

Spray foam insulation offers several advantages for a metal building, including:

- Good Thermal Properties - Spray foam insulation provides a high R-value.

- Air Sealing - It effectively seals cracks, gaps, and seams, preventing air leaks that can reduce energy efficiency.

- Moisture and Condensation Control - It creates a vapor barrier.

- Noise reduction - It helps dampen sound. reducing outside noiseIt doesn't prevent radiant heat transfer (the primary source of heat transfer into and out of a building - especially metal buildings and pole barns.

- Durability and Longevity - Unlike traditional insulation materials, spray foam adheres to the surfaces and does not sag.

- Pest and Rodent Resistance - It does not provide a food source for pests and helps seal entry points that rodents might use.

Disadvantages

While spray foam insulation offers many benefits for metal buildings, there are also some disadvantages to consider:

Higher Initial Cost – Spray foam insulation is more expensive upfront compared to traditional insulation materials like fiberglass or rigid board insulation.

Professional Installation Required – Proper application requires skilled professionals and specialized equipment, which can add to the overall cost.

Potential for Off-Gassing – Some spray foams release volatile organic compounds (VOCs) during installation, which can cause odors and require ventilation until they dissipate.

Difficult to Remove or Modify – Once applied, spray foam adheres tightly to surfaces, making it challenging to remove or alter if future modifications are needed.

Requires Proper Surface Preparation – The metal surface must be clean and dry before application to ensure proper adhesion, which can add to preparation time and labor.

Not UV Resistant – If exposed to direct sunlight, spray foam can degrade over time and may require a protective coating for long-term durability.

Potential for Trapping Moisture – If not properly applied, closed-cell foam can trap moisture between the insulation and the metal panels, leading to hidden corrosion issues.

Expansion Issues – Improper application or excessive thickness can cause foam expansion issues, which might warp metal panels or create uneven surfaces.

Flammability Concerns – While many spray foams include fire-retardant additives, they can still be combustible and may require additional fire-resistant coatings or barriers.

Prodex Total vs. Spray Foam Metal Building Insulation – See the detailed comparison

MJbirdie: Wednesday, March 02, 2020

Dear Insulation4Less,

The spay foam was flaking from the building I just bought. It was a mess. It took me two days to scrap the balance of it off. Your 10M went up quick. I used some big head screws and some metal strips to attach it to my framing. I could tell the difference instantly. Good stuff

John S. Wednesday, Feb 13, 2019

Dear Insulation4Less,

I was considering using spray foam for a retrofit of my 50 x 100 warehouse roof. My primary concern was condensation and heat. I'm glad I went your direction. In addition to saving money, I think I got a better product for my money given my needs. No issues of yet. I'll stay in touch.

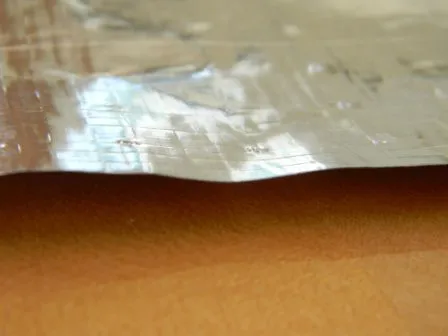

Bubble Insulation Compared to Prodex Total

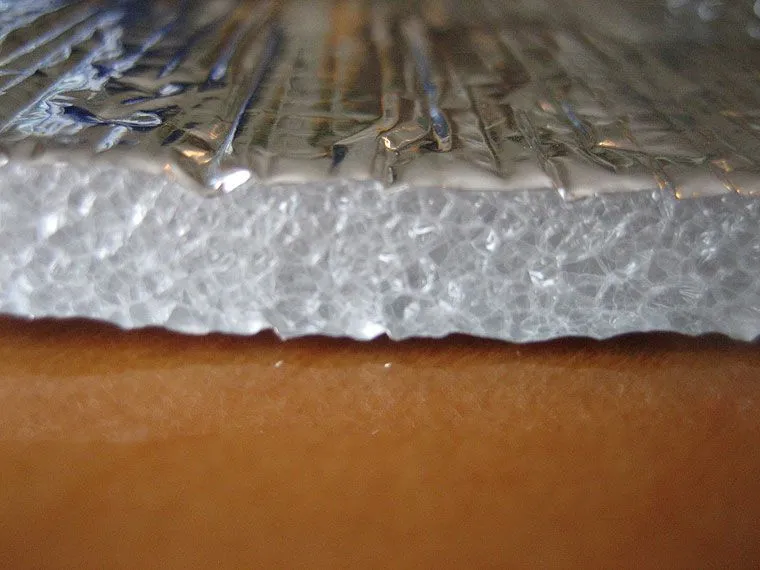

Take a look at the photos above. Even if you didn't know anything about double bubble insulation or Prodex Total, which would you choose? The obvious choice is Prodex Total. It has a high quality core that keeps its shape when exposed to forces. Prodex Total 5M plus has a nominal thickness of 5mm (0.2"). Prodex Total 10M is 10mm (0.4"). Both are closed cell polyethylene foam covered on both sides with reflective reinforced foil facing.

Under pressure, the Prodex micro-cells do not collapse -- With a pressure of 6 PSI Prodex compresses just 6%. When the load is relieved it takes back its initial shape. The density of the foam is between 1.25 lb/ft (sq) - 1.87/ft (sq). This gives the material real body.

Because Bubble insulation has a core composed of air rather than closed cell polyethylene foam, it lacks the long-term consistence in performance of Prodex Total. Learn more about bubble insulation.

Dear Insulation4Less,

My name is David. I am the Warehouse Manager for Schlossadler Wines, Inc. We are an international boutique wine distributor with a 9,300 sq. ft. warehouse in Oceanside, CA. Approximately one month ago the owner of the company (my boss) came to me with the task of researching, ordering, and installing insulation for the ceiling of the entire building by myself. With limited experience in this particular area under my belt, I accepted the project anyway. I honestly didn't even know where to start. I sent detailed photos along with our information and questions to your sales team. They replied promptly with very easy instructions and recommendations as to "what type" and "how much" product should be ordered to complete our mission. Now, one month and about 200 hours later, my boss is extremely happy, our stock is cool, and I've received a very generous bonus!!

Thanks Insulation4Less, I will definitely spread around the words: "foil-foam-foil!"

Sincerely,

David W.

Warehouse Manager

Schlossadler Wines, Inc.

Oceanside, CA

What do our customers say?

Insulation for metal buildings plays an important role in weather protection, noise and more. Without it, you can end up with leaks, mold, mildew and even unwelcome critters.

Whether you have a primary drive for insulating your metal building or you’re eager to reap the entire list of benefits, your insulation must stop heat, cold, condensation and air to provide the best value.

Metal building insulation can be used in commercial buildings and warehouses, airplane hangars and metal churches, barns and garages, garden sheds and Quonset huts, shipping containers, crawl spaces, and home structures, such as basements, attics and storage spaces.

In other words, if the structure requires protection from either, heat, cold, moisture or air, you’re likely to benefit from the protections of insulation.

Scorching sun, freezing wind or rattling hail? No problem. Deafening noise interrupting your home office meetings? Easily solved.

Prodex is a new-generation multifaceted product that serves as an all-in-one: it stops condensation, heat, cold and air, absorbs the sound of rain and hail, helps prevent rodents, bugs and birds, and prevents the occurrence of fungi like mold and mildew.

The reflective nature of Prodex keeps the temperature consistent on the inside and outside of the sheeting and prevents condensation. It creates an air barrier that is directly related to the safety of the building in case of fire.

Due to its light weight, it is easy to install, work with and transport, which makes it a preferred alternative for insulation of metal buildings, for both professional insulation companies and DIY homeowners.

In hot sunny climates, the use of radiant barriers like Prodex can significantly lower cooling costs due to decreased heat transfer and reduced need for air-conditioning appliances.

Insulation4less provides quality insulation for steel buildings corresponding to your needs, preferences and budget. We also provide fast delivery services, installation methods and expert advice to help ensure you get the best value for your money.

From our Fast Action Prodex Total to our 10M, we have many different Prodex options to choose from and each will leave you with lasting benefits for your metal building insulation project.

In home applications, Prodex Total is used as stand alone and supplemental insulation - The choice depends on your insulation needs.

Because bubble insulation has a core composed of air rather than closed cell polyethylene foam, it lacks the long-term consistency in performance of Prodex Total Insulation.

Bubble wraps are composed of either one (single bubble) or two (double bubble) layers of air bubbles sandwiched between two metalized surfaces. Once the surface of single or double bubble is punctured, it collapses.

Foil only radiant barriers are typically perforated and composed of two metalized surfaces with a mesh woven in for strength. It is not a vapor barrier - It is not insulation. Because foil only products have no membrane (substance between the layers of reflective material) transference of heat and or cold can occur.

Reflective Insulation is a system that reduces the transfer of heat across air space by the use of two surfaces having high thermal reflectance and low emittance (typically metalized film) + an inner substance + trapped airspaces.

The R-value of reflective insulation is the measurement of the system rather than a measurement of just the product. Measuring the R-value of the system (a real-world application) is a truer measurement vs. a measurement of the product only. For example, what good is the posted R-value of fiberglass given that once installed in an environment that includes any moisture it loses R-value? Virtually all real-world environments include some humidity. Unlike fiberglass the R-value of Prodex Total insulation is NOT affected by humidity.

Equipment needed: Reflective tape, a utility knife, a staple or screw gun

Insulation Over Trusses

- Drape the selected Prodex type over the trusses.

- Let the insulation sag a minimum of 2 inches.

- Apply decking.

- Apply the selected Prodex directly on the decking.

- Use 1”x 3” furring strips on top of the insulation.

- Install tiles.

- Apply the desired Prodex insulation directly on decking or shingles.

- Use 1”x 3” furring strips on top of the insulation.

- Install the metal roof.