Why Choose Prodex Total for Steel and Metal Buildings

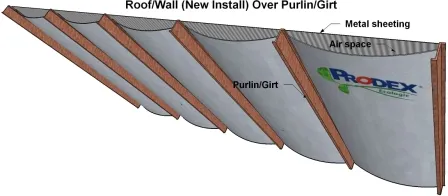

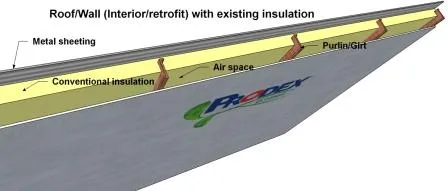

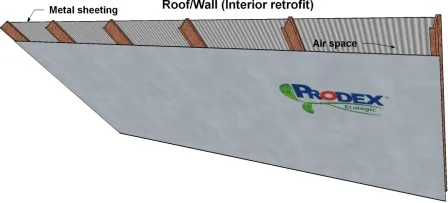

Traditional fiberglass insulation will absorb moisture and lose effectiveness over time. Spray foam won't stop the radiant heat. Bubble wrap, is merely a single or double row of air bubbles; consequently, it also loses effectiveness in time. Prodex Total eliminates those issues by combining multiple protective layers:

Reflective Radiant Barrier – Blocks up to 97% of radiant heat.

Vapor Barrier – Prevents condensation and corrosion.

Closed-Cell Core – Resists mold, mildew, and pests. Seals around nails, screws and staples.

It’s an all-in-one insulation system specifically engineered for metal and steel buildings — garages, barns, workshops, and commercial spaces alike.

Learn More About Metal Building Insulation

For deeper information and side-by-side comparisons, visit:

Metal Building Insulation – Stop Condensation, Heat, Cold, and Air

Prodex Total Insulation vs Fiberglass Insulation for Metal Buildings

Prodex Total Insulation vs Spray Foam Insulation for Metal Buildings